PE PP Sheet Extruder Machine,PVDF PEEK Sheet Extruder Machine,PA POM Sheet Extruder Machine,Hard PVC Transparent Sheet Extruder Machine,Soft PVC Transparent Sheet Extruder Machine,ABS Board Extruder Machine,PE PP Board Extruder Machine,PVC Sheet Extruder Machine,PS Sheet Extruder Machine,TPU Sheet Extrusion Machine,PVC Board Extruder Machine,Biodegradable Sheet Machine

Welcome to the world of advanced plastic machinery, where innovation meets reliability. At Qingdao Eaststar Plastic Machinery Co., Ltd., we specialize in crafting solutions that redefine efficiency and quality in the plastic processing industry. Our flagship PE PP Double-layer Co-extrusion Board Machine stands as a testament to our commitment to excellence. Designed for producing high-strength, versatile boards used in packaging, construction, and advertising sectors, this machine integrates cutting-edge co-extrusion technology to deliver boards with two distinct layers—typically combining polyethylene (PE) and polypropylene (PP)—for enhanced durability and performance. Whether you're in manufacturing, logistics, or retail, this machine empowers you to create custom boards that meet diverse application needs.

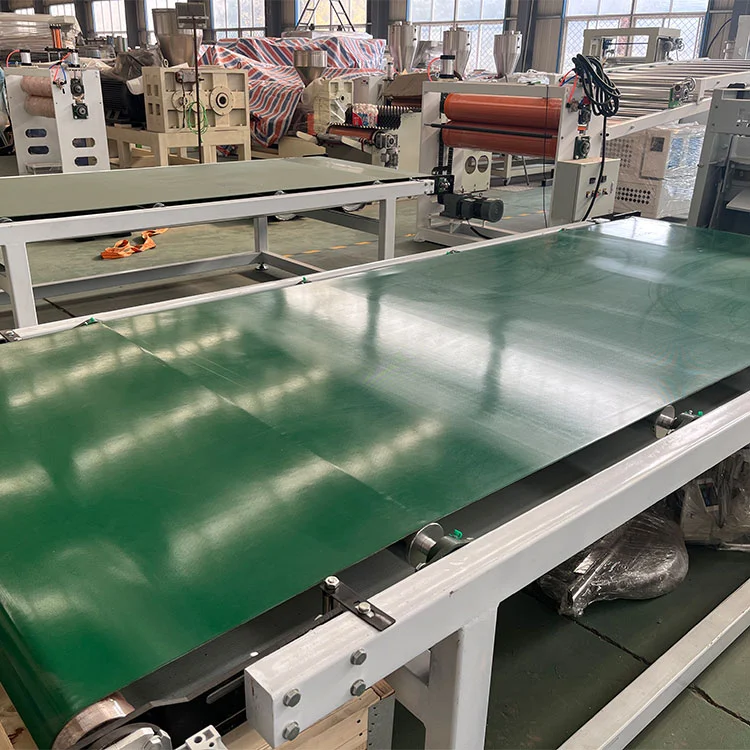

Imagine a machine that not only boosts productivity but also elevates the quality of your output. The PE PP Double-layer Co-extrusion Board Machine excels with its robust construction and intelligent design. Featuring precision temperature control, automated extrusion systems, and energy-efficient components, it ensures consistent board thickness and surface finish. The dual-layer extrusion process allows for material optimization, reducing waste while enhancing mechanical properties like impact resistance and moisture barrier. Users often report a seamless operation experience, thanks to its user-friendly interface and minimal maintenance requirements. Backed by Qingdao Eaststar's rigorous quality assurance, every machine undergoes thorough testing to guarantee long-term reliability and performance in demanding environments.

In industries where precision and efficiency are paramount, common challenges include inconsistent board quality, high material waste, and frequent downtime. Our PE PP Double-layer Co-extrusion Board Machine addresses these pain points head-on with innovative solutions. For instance, the integrated PLC system allows real-time monitoring and adjustments, ensuring uniform extrusion. Below is a table summarizing key parameters that highlight its capabilities:

| Parameter | Specification | Benefit |

|---|---|---|

| Extrusion Width | Up to 2500 mm | Enables production of wide boards for large-scale applications |

| Layer Thickness Control | Precision ±0.1 mm | Ensures consistent quality and reduces material variance |

| Production Speed | Adjustable up to 8 m/min | Boosts output while maintaining high standards |

| Power Consumption | Optimized for energy savings | Lowers operational costs and environmental impact |

This machine is ideal for businesses involved in packaging solutions, building materials, or advertising displays. Picture a packaging company that needs lightweight yet sturdy boards for shipping containers—our machine produces boards that withstand rough handling while being cost-effective. In construction, it creates insulating panels that improve energy efficiency. Users experience a sense of confidence and growth, as the machine solves issues like production bottlenecks and quality inconsistencies, leading to higher customer satisfaction and expanded market opportunities.

What sets the PE PP Double-layer Co-extrusion Board Machine apart from competitors is its unique combination of adaptability and sustainability. Unlike standard single-layer machines, it allows for material recycling and customization of layer properties, such as using recycled PE for the inner layer and virgin PP for the outer layer. This not only reduces carbon footprint but also caters to eco-conscious markets. Additionally, Qingdao Eaststar integrates advanced cooling systems and noise reduction technologies, making it a quieter and safer option for factory settings. The result is a machine that not only meets but exceeds industry standards, providing a competitive edge in today's fast-paced market.

Frequently asked questions help clarify common queries. Below are some detailed answers based on user feedback:

What is the typical lifespan of this machine?

With proper maintenance, the PE PP Double-layer Co-extrusion Board Machine can operate efficiently for over 10 years. Regular cleaning and part inspections, as recommended in the user manual, ensure longevity and consistent performance.

Can it handle different types of raw materials?

Yes, the machine is designed to process various grades of PE and PP, including recycled materials. The extrusion system adjusts automatically to material variations, maintaining output quality without frequent recalibrations.

How does it contribute to cost savings?

By optimizing material usage through precise layer control and reducing energy consumption, users typically see a 20-30% decrease in operational costs over time. The low maintenance design also minimizes downtime and repair expenses.

Is technical support available after purchase?

Qingdao Eaststar provides comprehensive support, including installation guidance, training, and 24/7 customer service. Spare parts are readily available to ensure uninterrupted production.

What safety features are included?

The machine comes with emergency stop buttons, overload protection, and insulated components to prevent accidents. It complies with international safety standards, ensuring a secure working environment.

Beyond specifications, the emotional impact of using this machine is profound. Business owners feel empowered as they streamline their production lines, reduce waste, and deliver superior products. In scenarios like creating custom advertising boards, the machine enables vibrant, durable outputs that capture attention and drive sales. The sense of achievement from overcoming production challenges fosters loyalty and innovation within teams.

In summary, the PE PP Double-layer Co-extrusion Board Machine by Qingdao Eaststar Plastic Machinery Co., Ltd. is more than just equipment—it's a partner in growth. Its ability to adapt to diverse needs, from industrial packaging to creative displays, makes it a versatile asset. By focusing on user-centric design and sustainable practices, it not only solves immediate problems but also paves the way for future advancements. Explore the possibilities and transform your production capabilities with a machine that embodies reliability and innovation.