PE PP Sheet Extruder Machine,PVDF PEEK Sheet Extruder Machine,PA POM Sheet Extruder Machine,Hard PVC Transparent Sheet Extruder Machine,Soft PVC Transparent Sheet Extruder Machine,ABS Board Extruder Machine,PE PP Board Extruder Machine,PVC Sheet Extruder Machine,PS Sheet Extruder Machine,TPU Sheet Extrusion Machine,PVC Board Extruder Machine,Biodegradable Sheet Machine

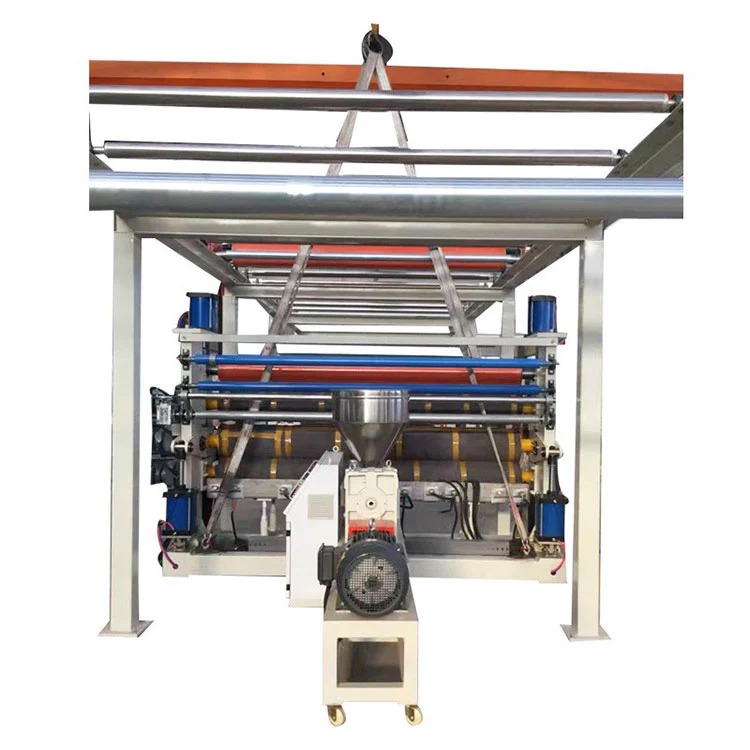

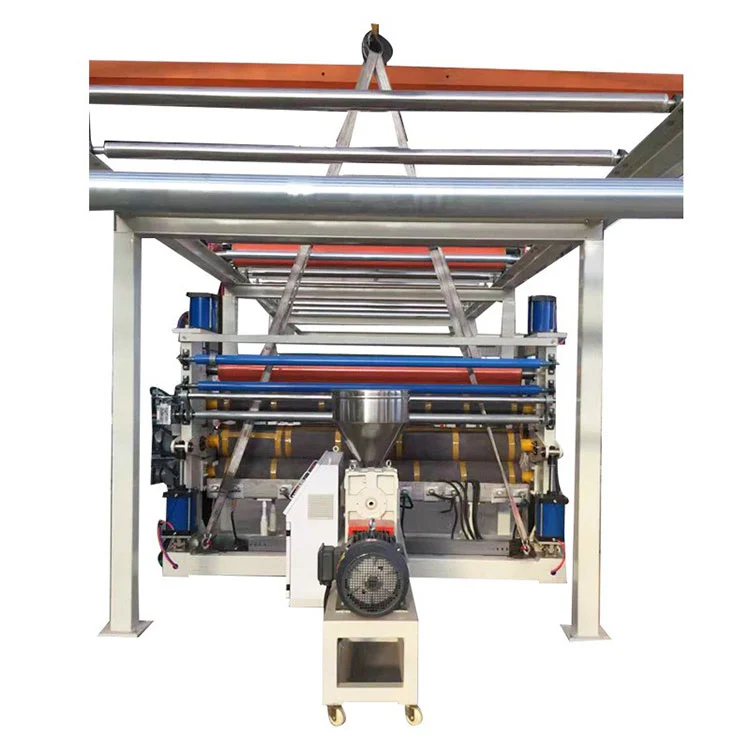

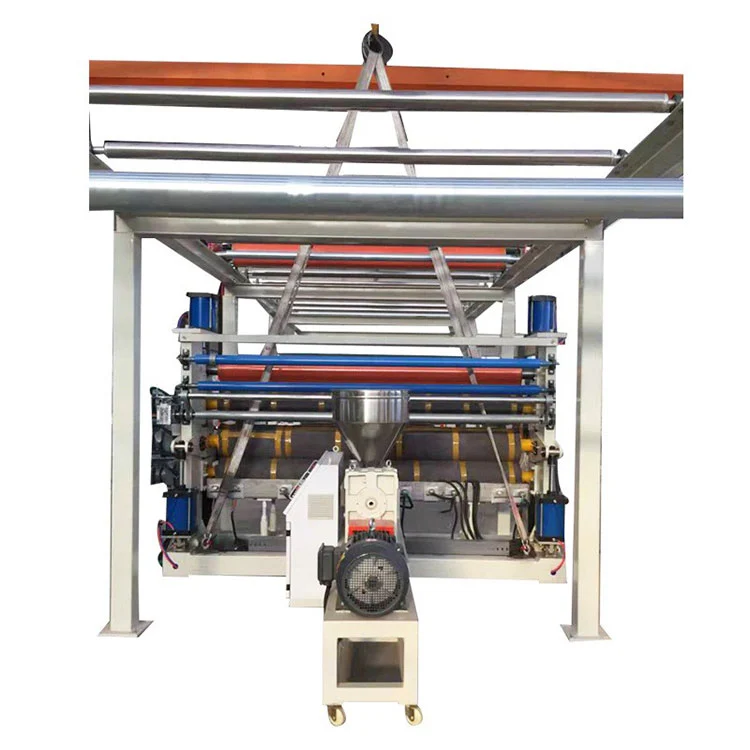

In the competitive world of automotive accessories manufacturing, efficiency and quality are paramount. The TPE Car Mat Sheet Extruder Machine from Qingdao Eaststar Plastic Machinery Co., Ltd. stands as a pioneering solution designed to meet the growing demand for high-performance, eco-friendly car mats. This advanced machine specializes in producing thermoplastic elastomer (TPE) sheets, which are increasingly favored for their durability, flexibility, and environmental benefits. By integrating cutting-edge extrusion technology, this machine ensures consistent output for automotive flooring applications, helping manufacturers stay ahead in a dynamic market.

At its core, the TPE Car Mat Sheet Extruder Machine transforms raw TPE materials into uniform sheets ideal for car mats. These sheets offer superior resistance to wear, weather conditions, and chemicals, making them a preferred choice for modern vehicles. The machine's versatility allows for customization in thickness, texture, and color, enabling producers to cater to diverse automotive brands and consumer preferences. Whether for OEM suppliers or aftermarket manufacturers, this extruder streamlines production while upholding stringent quality standards.

What sets the TPE Car Mat Sheet Extruder Machine apart is its blend of innovative engineering and user-centric design. One of the standout features is its energy-efficient operation, which reduces power consumption by up to 20% compared to conventional extruders. This not only lowers operational costs but also aligns with sustainable manufacturing practices. The machine incorporates a precision temperature control system that maintains optimal processing conditions, minimizing material waste and ensuring consistent sheet quality. Additionally, its robust construction using high-grade components guarantees longevity, even in high-volume production environments.

Another key benefit is the enhanced safety mechanisms, including automatic shutdown in case of anomalies, which protect both the equipment and operators. The intuitive interface allows for easy monitoring and adjustments, reducing the need for specialized training. With Qingdao Eaststar Plastic Machinery Co., Ltd.'s commitment to excellence, each machine undergoes rigorous testing to deliver reliable performance, backed by comprehensive after-sales support. This focus on durability and ease of use translates to higher productivity and fewer downtime incidents, empowering businesses to scale efficiently.

This extruder is ideal for automotive parts manufacturers, recycling facilities, and startups venturing into eco-friendly products. In bustling factories, it addresses the challenge of meeting tight deadlines without compromising on quality. For instance, a manufacturer struggling with inconsistent mat thickness can achieve uniformity, reducing rejection rates and enhancing customer satisfaction. The machine also supports the production of custom designs, such as anti-slip patterns or branded logos, opening doors to niche markets. Beyond cars, the sheets can be adapted for commercial vehicles, boats, or even industrial flooring, showcasing its adaptability.

Users often report a sense of confidence and pride in delivering products that exceed safety and aesthetic standards. By solving common issues like material degradation or color fading, the TPE Car Mat Sheet Extruder Machine fosters trust with end-consumers, who appreciate mats that last longer and are easier to clean. This emotional payoff extends to business owners, who see improved brand reputation and increased repeat orders, ultimately driving growth in a competitive landscape.

To help you evaluate how this machine fits your needs, here are some key parameters presented in a clear format. These details address typical pain points, such as output variability or maintenance frequency, by highlighting the extruder's capabilities.

| Parameter | Specification | Benefit |

|---|---|---|

| Output Capacity | Up to 500 kg/hour | High efficiency for mass production |

| Sheet Thickness Range | 1-10 mm | Versatility for various applications |

| Power Consumption | 25-40 kW (depending on model) | Energy savings and cost reduction |

| Control System | PLC with touch screen | Easy operation and real-time monitoring |

| Warranty Period | 2 years on main components | Long-term reliability assurance |

These specifications demonstrate the machine's ability to handle diverse production demands while maintaining precision. For example, the adjustable thickness allows manufacturers to create lightweight mats for compact cars or heavy-duty versions for trucks, all with minimal setup time.

Unlike many standard extruders, the TPE Car Mat Sheet Extruder Machine from Qingdao Eaststar Plastic Machinery Co., Ltd. features a unique dual-stage cooling system that enhances sheet stability and reduces curing time. This innovation leads to a smoother surface finish and higher tensile strength, giving end-products a premium feel. Furthermore, the machine supports the use of recycled TPE materials, appealing to environmentally conscious brands. Its modular design allows for easy upgrades, ensuring it remains relevant as technology evolves. Competitors often lack this flexibility, making our extruder a forward-thinking investment.

Customer testimonials frequently highlight the exceptional after-sales service, including remote troubleshooting and spare parts availability, which minimizes operational disruptions. This holistic approach—combining advanced technology with unwavering support—creates a distinct advantage in the marketplace.

What types of TPE materials are compatible with this machine?

The extruder works with a wide range of TPE compounds, including virgin and recycled variants. It is optimized for materials with specific melt flow indices to ensure smooth processing and high-quality output. For best results, consult our technical team for material recommendations based on your production goals.

How does the machine handle maintenance and cleaning?

Routine maintenance is straightforward, with accessible components and clear guidelines provided in the manual. The self-cleaning features reduce downtime, and our support team offers training sessions to help your staff perform basic upkeep efficiently.

Can the extruder produce sheets with custom colors or patterns?

Yes, it includes a color mixing unit and pattern embossing options. This allows for full customization to match brand requirements or consumer trends, without significant retooling costs.

What is the typical lead time for delivery and installation?

Delivery times vary based on order volume and location, but we strive to dispatch within 4-6 weeks. Installation services are available globally, with on-site support to ensure a smooth setup process.

Does the machine come with training for operators?

Absolutely. We provide comprehensive training modules, including hands-on sessions and digital resources, to empower your team to operate the machine safely and effectively from day one.

In summary, the TPE Car Mat Sheet Extruder Machine embodies innovation and reliability, tailored for modern manufacturing challenges. By choosing Qingdao Eaststar Plastic Machinery Co., Ltd., you invest in a partnership dedicated to your success, with tools that enhance productivity and product quality. Explore how this machine can transform your production line and elevate your offerings in the automotive sector.